Alle categorieën

Welkom bij Imlab!

Sinds 1993 zijn we verdeler van labo apparatuur en weegschalen voor industrie, voeding, laboratorium en de medische sector.

Onze merken

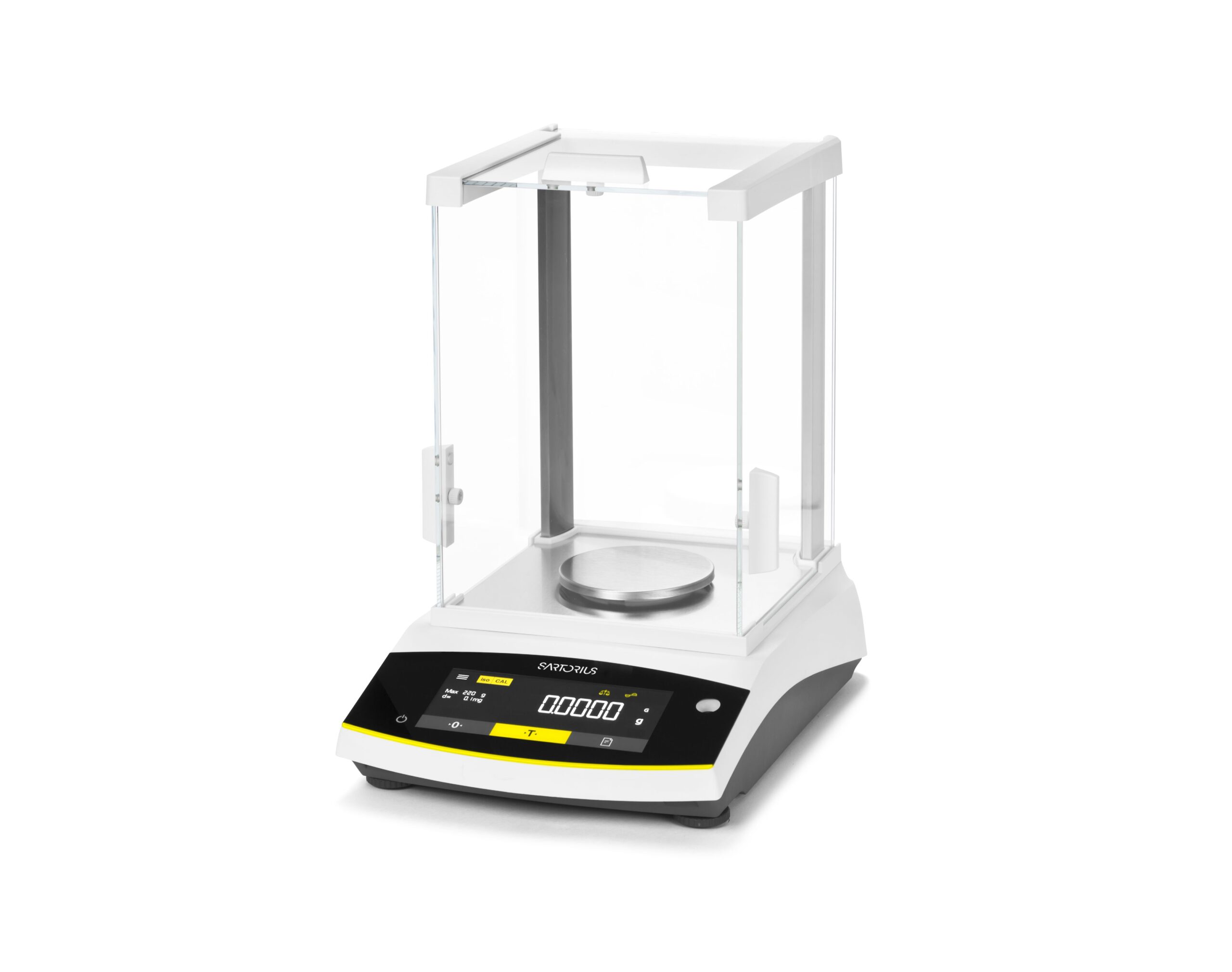

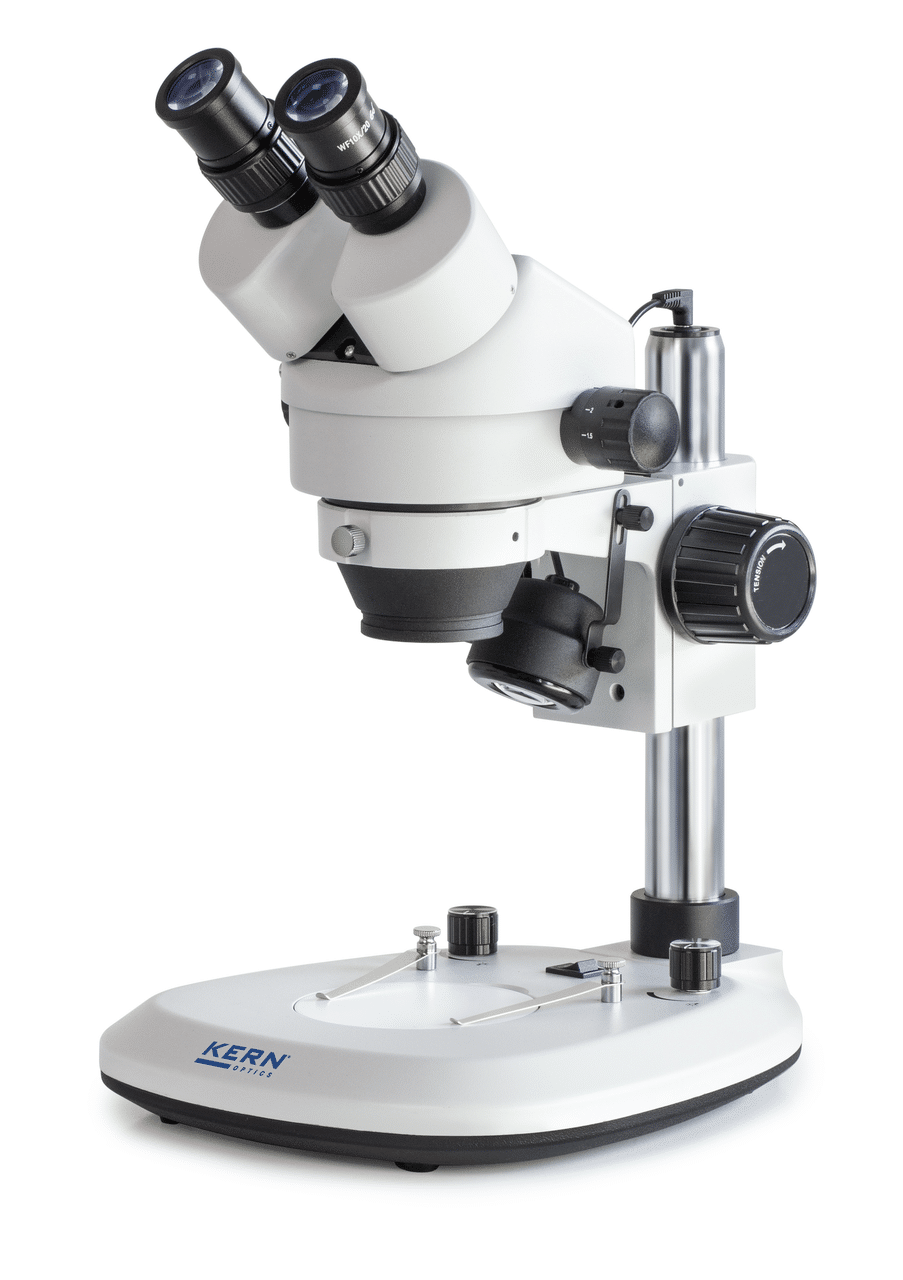

Onze bestsellers

Al 30 jaar producten van hoge kwaliteit en met de beste service

Alleen het beste op de markt

Meer dan 10.000 producten én hun accessoires die voldoen aan de de strengste veiligheidsnormen als kwaliteitseisen.

Lees meerPersoonlijke service

We vinden het belangrijk een hechte samenwerking te onderhouden met onze klanten.

Lees meerGratis verzending

Gratis verzending voor orders in de webshop van > € 400,00 (uitgezonderd verzending op pallet).

Lees meerPopulaire categorieën

Promoties

Advies nodig?

Stel je vraag aan onze product specialisten, we helpen je graag!